Quality Assurance

ThermoBeast Quality Assurance

Redefining safety standards for thermal products, ensuring every warmth meets rigorous quality benchmarks

Brand Commitment: Safety-First Philosophy of Thermal Technology

ThermoBeast has always put user safety at the heart of product development, and every piece of heated clothing has undergone safety processes and extreme weather testing. We know that keeping warm shouldn't be a risk – when you put on the ThermoBeast, you'll get the right temperature for you, plus military-grade security.

Cold weather test

Each product undergoes a heating test at -40°F.

Trustworthy Safety Data

Product Safety Pass Rate

Warranty for Core Components

Safe Global Users

Serious Safety Incidents

Core Safety Certifications: Visible Peace of Mind

UN38.3 Battery Safety

Custom 5000mAh lithium polymer battery passes rigorous aviation transportation safety tests, ensuring safe operation under extreme conditions.

UL 2056 Safety

Complies with North American safety standards for power banks, including short-circuit protection, overcharge prevention, and thermal management.

FCC Certification

Meets U.S. Federal Communications Commission standards for electromagnetic compatibility, ensuring minimal interference with electronic devices.

MSDS Compliance

Comprehensive safety data sheet available, detailing chemical composition, hazard information, and proper handling procedures.

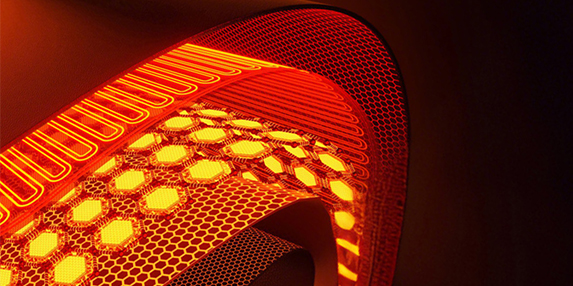

ADVANCED HEATING TECHNOLOGY

Experience our cutting-edge heating system featuring aerospace-grade materials and intelligent temperature control. Our proprietary honeycomb heating wire ensures uniform warmth while maintaining safety and durability. Trust in technology that delivers consistent performance in extreme conditions.

Explore Advanced Heating Technology

OUR BRAND STORY

Founded on the principles of innovation and reliability, ThermoBeast was born from a passion to redefine heated apparel. Since our inception, we've combined military-grade engineering with everyday comfort, earning trust through rigorous testing and customer-centric design. Discover the journey behind America's most trusted heated clothing brand.

Discover Our Brand Story

STATE-OF-THE-ART MANUFACTURING

Step inside our advanced manufacturing facility where precision meets innovation. Every ThermoBeast product is crafted with meticulous attention to detail, using sustainable practices and cutting-edge automation. Our commitment to quality control ensures each garment meets our strict safety and performance standards before reaching you.

Tour Our State-of-the-Art Factory

Black Technology Safety System: Three-Layer Protection Barrier

Military-Grade Heating Wire Protection

- Aerospace-grade nickel-chromium alloy heating wire, 0.3mm diameter with 10,000-bend lifespan

- Patented honeycomb weaving structure for uniform heat distribution within ±2℃ error

- Waterproof breathable membrane wrapping technology maintains circuit insulation even if surface is punctured

Overheat Protection Technology

- Overheat protection technology is a critical safety feature designed to prevent burns or fire hazards caused by excessive heat in heated garments.

- Environmental temperature adaptive system: switches to moisture-proof mode when external humidity >80%

- In carbon fiber heating apparel, this technology plays a vital role in safeguarding user safety.

Rugged Composite Housing Design

- The battery housing is constructed from a high-impact polycarbonate blend that provides outstanding durability and protects the internal battery and circuitry.

- This ruggedized case resists drops, impacts, and everyday wear and tear.

- The case features a matte, non-slip finish and Thermo Beast branding for safe, long-lasting performance and a comfortable, ergonomic feel.